A world where we work, learn, play, relax, and eat with robots every day

How Will Robotics Change Logistics in 2030/2040?

The Logistics Industry Faces Serious Workforce Shortages

When you order goods online, most likely you can receive them at home the next day, and if you send a package, you can rest assured that it will be delivered within the specified time range. The Japanese logistics system has achieved a level of convenience and security unparalleled by any other country. The industry, however, is now facing a serious challenge.

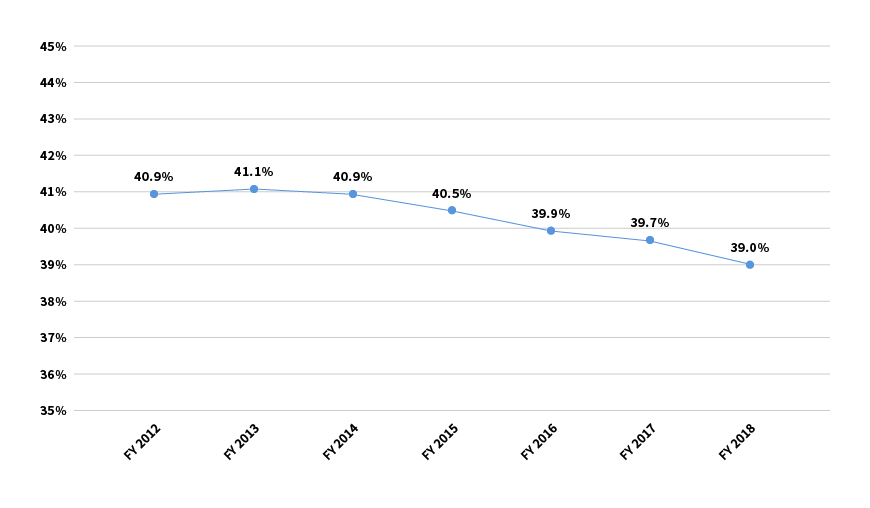

The growth in the number of home deliveries due to the rapid expansion of the e-commerce market (by a factor of 2.5 over the last ten years) and the spread of just-in-time production in the manufacturing industry have driven the logistics toward lower volumes per delivery and higher delivery frequencies. As a result, the load efficiency of commercial vehicles such as freight trucks is declining year by year (Figure 1).

Yearly Trend in the Load Efficiency of Commercial Freight Cars

Source: Created by Mitsubishi Research Institute based on “Annual Report of Motor Vehicle Transportation Statistics” by Ministry of Land, Infrastructure, Transport and Tourism

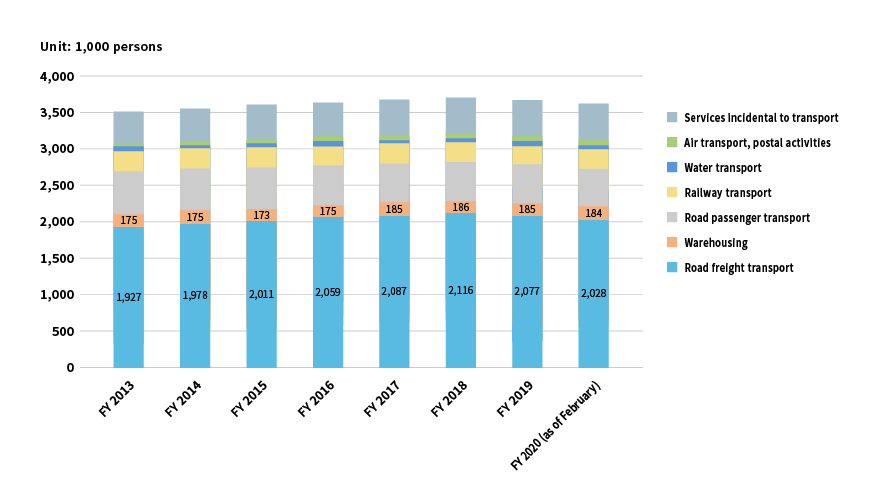

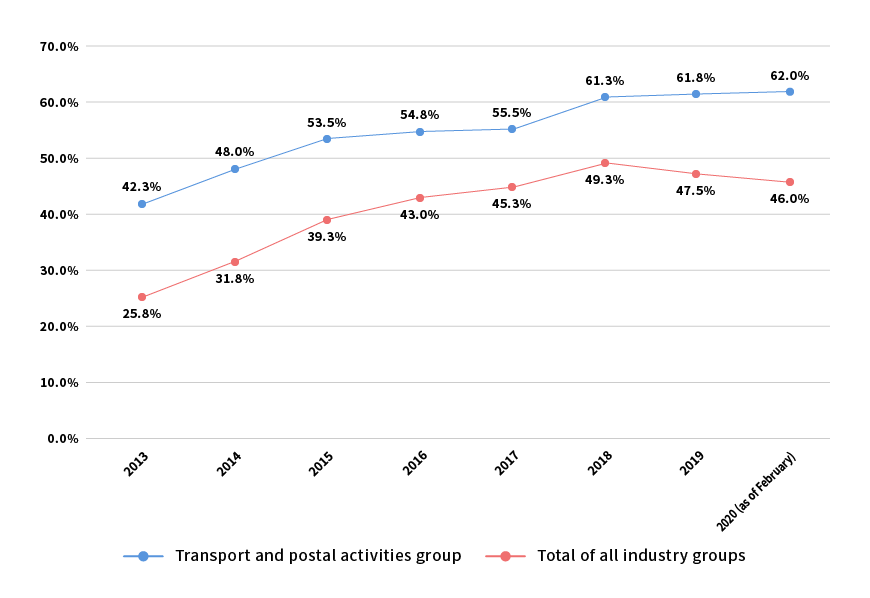

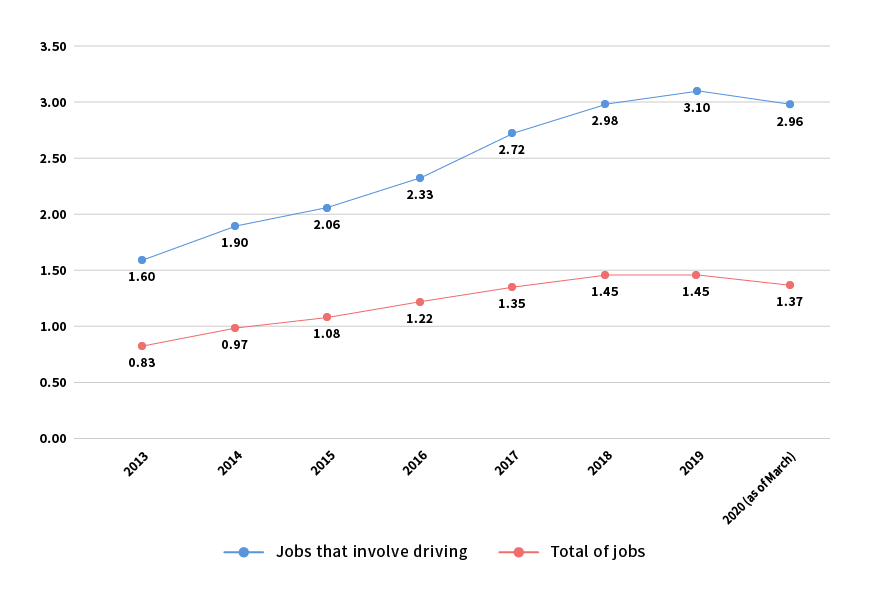

Moreover, harsh working conditions in the industry such as long working hours and low wages are slow to improve because the market structure entails high pressure from shippers to reduce costs. Although the industry is working to secure an adequate workforce, it is having a hard time attracting young people due to the rather unattractive working conditions. Consequently, the Japanese logistics workforce is aging at a faster rate than in other industries and labor shortages are becoming a serious problem (Figures 2, 3 and 4).

Yearly Trends of the Average Number of Persons Working at the Location of Enterprise and Establishment in the Transport and Postal Activities Group

Source: Created by Mitsubishi Research Institute based on "Survey on Service Industries" by Ministry of Internal Affairs and Communications

Yearly Trends in the Average Ratio of Enterprise and Establishment Experiencing Labor Shortage in the Transport and Postal Activities Group

Source: Created by Mitsubishi Research Institute based on “Survey on Labour Economy Trend” by Ministry of Health, Labour and Welfare

Yearly Trends in the Average Number of Active Job Openings-to-Applicants Ratio (Including Part-Timers) for Jobs That Involve Driving

Source: Created by Mitsubishi Research Institute based on "Report on Employment Security Statistics" by Ministry of Health, Labour and Welfare

The current COVID-19 pandemic has prompted consumers to refrain from going out and instead use e-commerce sites to purchase daily commodities, groceries, and takeout food, causing rapid growth in the demand for home delivery services. Amidst this situation, the last mile of logistics, in other words, the final step of the delivery process from the distribution center to the end user, is becoming a key challenge as consumer needs are outgrowing the capacity of the existing logistics network. In response, attempts have been made by some IT service providers to fill the labor gap in the logistics industry. For instance, Amazon and Uber are introducing tools to enable small operators and individuals to enter the delivery market. Meanwhile, logistics warehouse operations are suffering from an even more serious labor shortage under the pandemic because indoor work is unavoidable in warehouses. This is resulting in shipment delays and thus the labor shortage in the logistics industry has become felt by consumers.

Current Status of Robot Utilization in the Logistics Industry

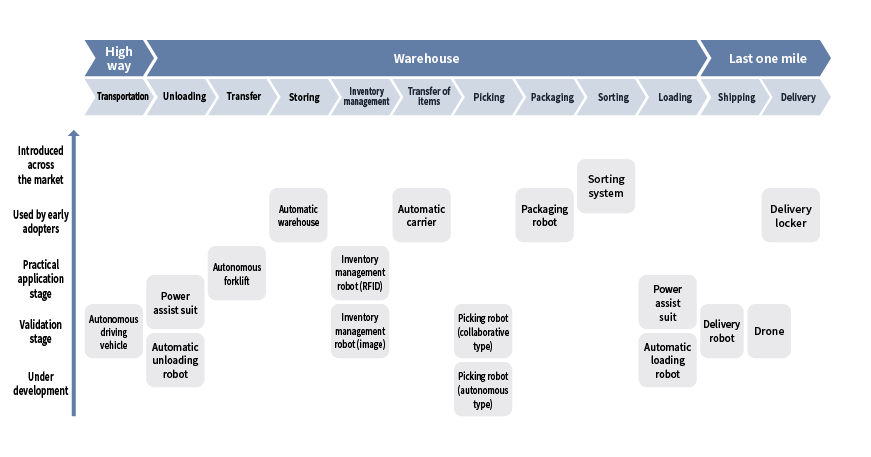

Amid these challenges, the logistics industry is actively introducing robots to save labor by automating various operations. The extent of robot utilization in the logistics industry is second only to the manufacturing industry. From here, we will look into the current status of robot utilization in the different steps of the logistics supply chain mainly focusing on warehouse and last-one-mile operations (Figure 5).

Robot Utilization in Various Steps in the Logistics Supply Chain

Source: Mitsubishi Research Institute, Inc.

Many large-scale logistics warehouses are starting to introduce robots to take over tasks such as placing/storing, packaging, and sorting items. On the other hand, tasks like loading, unloading, and picking items remain largely reliant on manual labor as the use of robots for these tasks is still limited.

If a highly versatile picking robot is developed that is capable of handling diverse items including heavy, fragile, soft, and amorphous ones, it will mark a significant step toward the full automation of logistics warehouses. Many companies from logistics giants to IT and robotics startups are competing to develop a versatile picking robot, as such a robot would boost efficiency and bring huge value to the logistics industry (Figure 6). For example, Amazon which boasts one of the world’s largest R&D spending is investing an enormous amount of money to automate its logistics warehouses. The practical application of a highly versatile picking robot is difficult, however, and it is estimated that it will take at least 10 more years to see a fully automated warehouse.

Examples of Robots Used in Logistics Warehouses

Photo: provided by Daifuku Co., Ltd.

"Amazon Robotics"

Photo : provided by Amazon Japan G.K.

"CMC CartonWrap"

Photo : provided by CMC S.r.l. (Italy)

Photo : provided by Daifuku Co., Ltd.

"De-palletizing Robot System"

Photo : provided by Kyoto Robotics Corporation

The Future of Robot Utilization in the Logistics Industry

Large-scale logistics warehouses will approach full automation by 2030

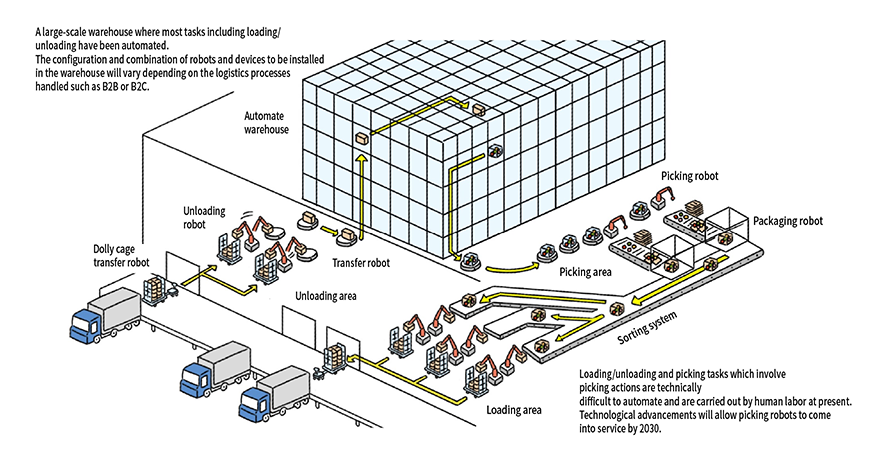

The loading/unloading and picking tasks in a logistics warehouse have not yet been automated and employs most of the workforce. However, e-commerce platform operators like Amazon and third party logistics (3PL) providers*1 are actively investing in R&D. State-of-the-art logistics warehouses are expected to be developed, replacing most labor-consuming tasks with robots in around 10 years by 2030 (Figure 7).

Image of a Highly Automated Logistics Warehouse in 2030

Source: Mitsubishi Research Institute, Inc.

Fast Retailing, the holding company of Uniqlo, announced in 2018 that it achieved 90% reduction of manual labor at its e-commerce center warehouse in Ariake, Tokyo*2. If efforts of this kind continue, it is estimated that the number of personnel working at logistics warehouses will be reduced by factor of 10 from the present.

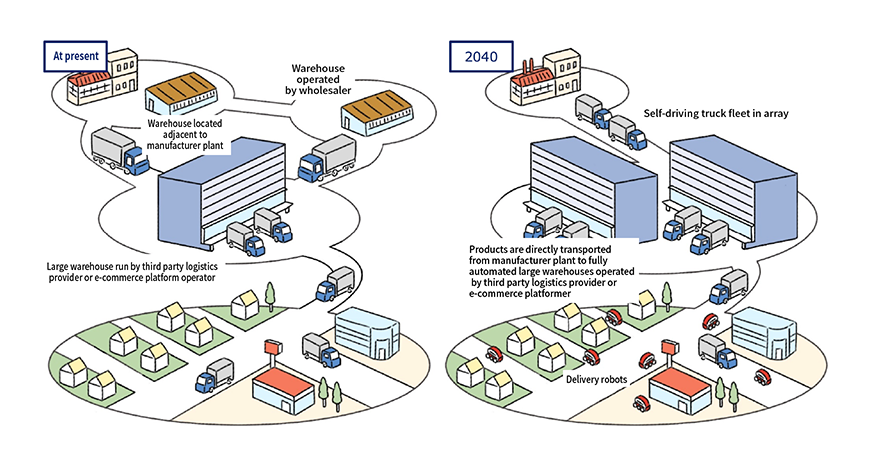

By 2040, Logistics Operations Will Be Aggregated at Fully Automated Large-Scale Warehouses

There are currently several tens of thousands of logistics warehouses operating in Japan, but only a limited number of warehouses will be automated with robots. This is because a minimum floor area is necessary for the effective operation of robots, but most warehouses in Japan are too small for robots to move around. Besides, the large amount of investment associated with the introduction of robots cannot be effectively recovered unless a certain level of item handling constantly takes place in the warehouse. These conditions would limit the introduction of robots to large-scale warehouses.

Small and medium-sized warehouses run by manufacturers and small-to-medium wholesalers who cannot afford to make large investments will be abandoned one after another when the time comes for renovation decades after construction. This is because they are less efficient than automated large-scale logistics warehouses managed by e-commerce platform operators and third-party logistics providers. As smaller warehouses are replaced by larger ones, investment in warehouse robotics will accelerate. It is expected that full automation of warehouses will be achieved by 2040, if not by 2030. It is projected that those facilities that have achieved a higher level of efficiency will absorb the operations of conventional facilities, and eventually, most logistics operations will be aggregated at fully automated large-scale warehouses (Figure 8).

Logistics Operations Will Be Aggregated at Fully Automated Large-Scale Warehouses by 2040

Source: Mitsubishi Research Institute, Inc.

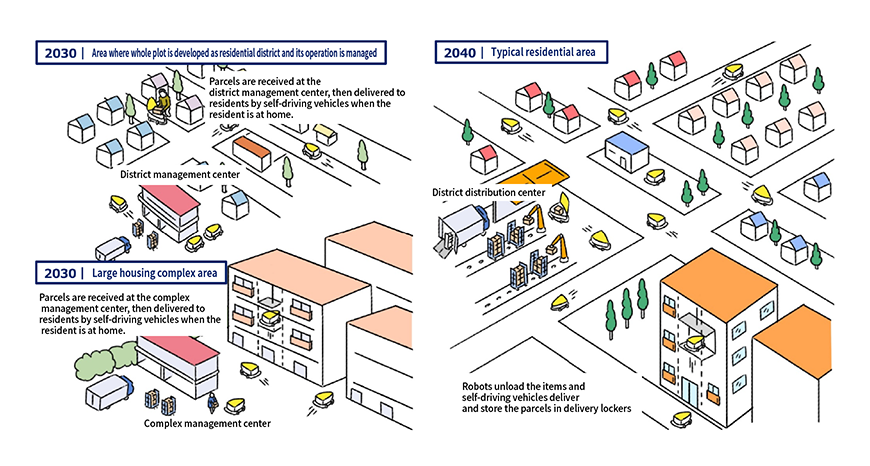

Autonomous Last-One-Mile Delivery Solutions to Gradually Spread Through 2030 to 2040

A number of companies are now developing delivery robots to automate the last one mile of the delivery process. Validation testing is already underway on public roads in the US and China. In Japan too, validation experiments are conducted within office buildings and university campuses (Figure 9). It is assumed that introduction of delivery robots may start by around 2030 in limited areas with suitable environments such as concentrated large condominiums or specific districts that meet certain conditions.

Examples of Delivery Robots Under Development

Photo : provided by ZMP Inc.

Photo : provided by Nuro, Inc. (USA)

Automobile manufactures around the world are engaged in fierce competition in the development of level 5 autonomous vehicles. These fully autonomous cars are expected to be put to practical use by around 2030, and by 2040 self-driving truck fleets will be running on highways playing an important role in interregional trunk transport.

On the other hand, the application of completely autonomous vehicles to last-one-mile services will require more time to be realized because it involves driving in a complex residential environment where people and pets walk around and many obstacles are encountered. Before any kind of autonomous car or delivery robot can be used for last-one-mile purposes, an appropriate environment will need to be created based on validation test results. This will include review of road traffic and development of an appropriate institutional design as well as improvement of road infrastructure to allow for the smooth operation of robots. As smart cities that meet these requirements emerge, perhaps around 2040, we will gradually begin to witness delivery robots operating in typical Japanese residential areas where single-family homes line the road. Autonomous last-one-mile delivery solutions will be adopted step by step and come into widespread social use from around 2040 (Figure 10).

Last-One-Mile Delivery in 2030-2040

Source: Mitsubishi Research Institute, Inc.

Challenges and Solutions Toward the Future of Robot Application

The Japanese logistics system has achieved world-class reliability, punctuality and security. Despite pressing labor shortages and the anticipated shrinking population, there will be strong demand for efficiency throughout the logistics system and its automation through the introduction of robotics. But then again, there are many challenges, not only technological but also in terms of social institutions and infrastructure, that need to be overcome to progress toward the future of robot application throughout 2030-2040 as envisioned above (Table 1).

List of Challenges to Overcome and Solutions Toward the Future of Robot Application

| Challenges to overcome | Solutions |

|---|---|

|

【Logistics warehouse】 |

【Development of element technologies】

【Develop an environment to accommodate the operation of robots】

|

|

【Last-one-mile delivery】 |

【Validation testing of autonomous driving in complex environments】

【Review of the legal system and institutional design】

【Infrastructure development】

|

|

【Overall】 |

【Reducing the cost of robots】

【Shifting the supply chain to yield better benefits of introducing robotics】

|

Source: Mitsubishi Research Institute, Inc.

In order to accelerate the introduction of robotics to logistics warehouses, it is important to develop not only element technologies but also an environment to accommodate the operation of robots. For instance, the specifications of pallets, cages and dollies used for carrying goods in the warehouse need to be standardized across the industry. It would also be helpful to introduce RFID technology to provide robots with detailed information on the weight and handling instructions of each item. Based on the assumption that robots will fail and handling errors will happen, both operational and spatial design of the facility need to be devised so as to facilitate efficient and safe interaction between humans and robots.

Introduction of delivery robots to last-one-mile services will require the revision of laws and other institutional designs, the development of appropriate infrastructure as well as the perfection of self-driving technologies. In Japan, pedestrians, bicycles, and automobiles are separated on some roads, but share the same space on others. It is therefore important to establish reliable traffic mechanisms and rules to ensure safe and smooth traffic that takes into account pedestrians, bicycles, automobiles, and delivery robots. Perhaps someday, a network of different types of delivery robots may be formed, in which parcels are relayed from a driveway-specialized delivery robot to a different delivery robot designed to travel on sidewalks.

The key factor that will determine whether such robots will be widely adopted or not is cost performance. If we try to include all the required functions in one robot, the robot will be loaded with various additional features and become expensive. Even if the cost could be lowered by mass production, it would not be easy to overcome the cost barrier. When we include the costs of infrastructure development and institutional design, the overall cost would be huge. Even in China, the world’s leading robotics supplier and home to several of the world’s smart cities, low paid workers still bear most of the workload in warehouse operations and last-one-mile delivery.

How are we to develop appropriate infrastructure for robot operation? How shall we design social systems? How shall we set down the rules for human interaction with robots? And how can we ensure the safety of humans as well as robots? Not only robotics engineers but also various stakeholders and experts need to share their wisdom to re-design the whole of society and build a logistics system that will provide the necessary underlying support for an expected shrinking society.

- *1:Third party logistics (3PL) providers: Specialized logistics operators who undertake the logistics operations of other organizations on a long term and comprehensive basis

-

*2:"Fast Retailing and Daifuku Conclude Strategic Global Partnership" (press conference held on Tuesday, October 9, 2018)

https://www.fastretailing.com/eng/ir/news/1810091300.html (Accessed : May 8, 2020)